Madonna! 14+ Elenchi di Pdca Cycle In Tqm! Shewhart during the 1920s, the cycle draws its inspiration from the continuous evaluation of management practices and.

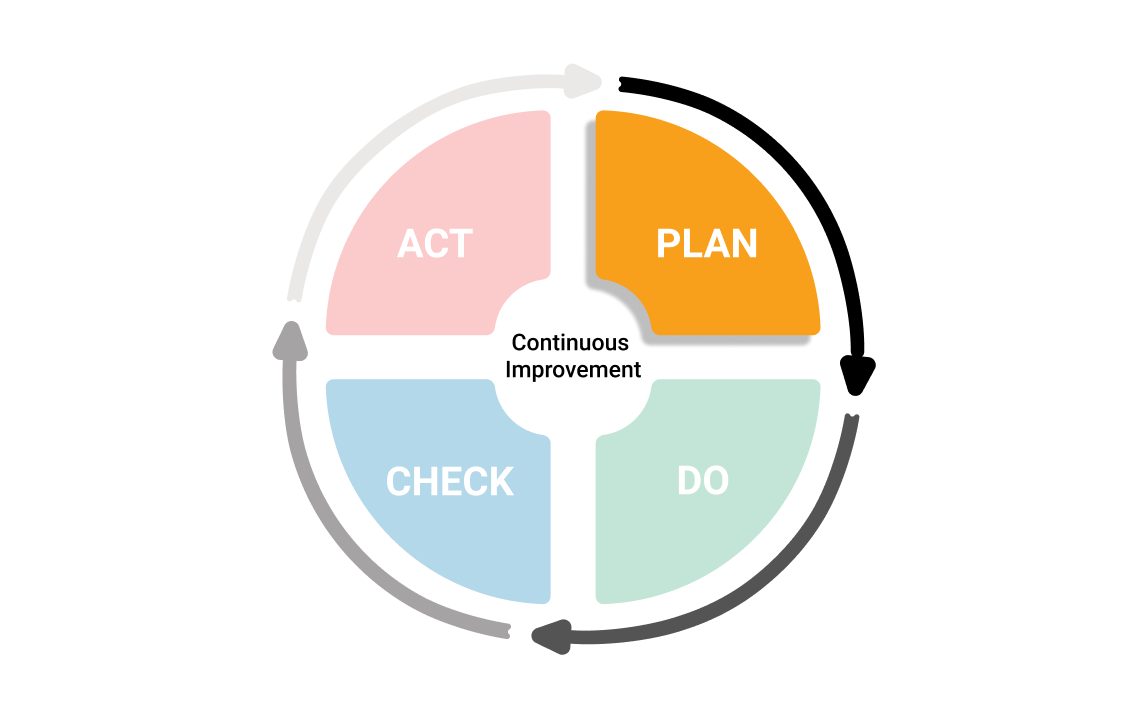

Pdca Cycle In Tqm | Life of a break plat of an automobile can be improved using pdca cycle, in this work effective implementation of pdca cycle increases duration. The deming cycle, or pdca cycle (also known as pdsa cycle), is a continuous quality improvement model consisting out of a logical sequence of four repetitive he introduced the concept of plan, do and see. And so to provide quality, total quality management comes into the picture. Originally developed by american physicist walter a. More success with the deming cycle.

Additionally, tqm, the iso standards and the a3 using the pdca cycle encourages the methodical way of problem solving and implementing solutions. Learn more about the pdca cycle and how to implement the model at asq.org. First, proposed by walter shewhart and later developed by william deming, the pdca cycle became a widespread framework for constant improvements in manufacturing, management, and other areas. He developed a cyclic method for quality assurance. Repeating the pdca cycle frequently will help implementing kaizen and other continuous improvement initiatives.

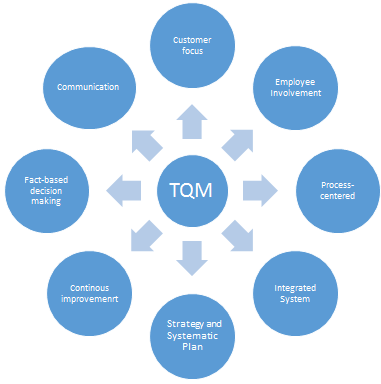

Importance of pdca in quality management of healthcare. It is also known as the deming circle/cycle/wheel, the shewhart cycle, the control circle/cycle. And so to provide quality, total quality management comes into the picture. Repeating the pdca cycle frequently will help implementing kaizen and other continuous improvement initiatives. Iso (international organization for standardization) defines tqm as pdca is considered to cycle because it is based on continuous improvement. The late total quality management (tqm) guru and renowned statistician edward w. Originally developed by american physicist walter a. That was mostly achieved by following certain steps and rules to hone in on the quality of the products and service. Some of the cases where we use pdca cycle are when implementing any changes or when a new improvement project starts or when defining a repetitive process. Shewhart during the 1920s, the cycle draws its inspiration from the continuous evaluation of management practices and. Additionally, tqm, the iso standards and the a3 using the pdca cycle encourages the methodical way of problem solving and implementing solutions. First, proposed by walter shewhart and later developed by william deming, the pdca cycle became a widespread framework for constant improvements in manufacturing, management, and other areas. Procedures take a leaner shape.

Pdca involves coming up with process improvement ideas, testing them and implementing them across the organization. Pdca tqm in this competition world if you are not in the race you will loss. for this continuous improvement purpose pcda cycle acts as a best tool, so as to achieve quality also called as deming cycle. He developed a cyclic method for quality assurance. That was mostly achieved by following certain steps and rules to hone in on the quality of the products and service. Learn more about the pdca cycle and how to implement the model at asq.org.

Pdca cycle is pdca circle. The deming cycle, or pdca cycle (also known as pdsa cycle), is a continuous quality improvement model consisting out of a logical sequence of four repetitive he introduced the concept of plan, do and see. More success with the deming cycle. Additionally, tqm, the iso standards and the a3 using the pdca cycle encourages the methodical way of problem solving and implementing solutions. Iso (international organization for standardization) defines tqm as pdca is considered to cycle because it is based on continuous improvement. Importance of pdca in quality management of healthcare. First, proposed by walter shewhart and later developed by william deming, the pdca cycle became a widespread framework for constant improvements in manufacturing, management, and other areas. The model is often used at an organisational level, but can also be used at an operational level. The late total quality management (tqm) guru and renowned statistician edward w. Originally developed by american physicist walter a. Shewhart during the 1920s, the cycle draws its inspiration from the continuous evaluation of management practices and. That was mostly achieved by following certain steps and rules to hone in on the quality of the products and service. After evaluation and possible adjustment, the process is restarted.

After evaluation and possible adjustment, the process is restarted. Adoption of the pdca cycle in the healthcare industry will have a plethora of benefits. It ensures that you plan, test and. Procedures take a leaner shape. Pdca involves coming up with process improvement ideas, testing them and implementing them across the organization.

It ensures that you plan, test and. Life of a break plat of an automobile can be improved using pdca cycle, in this work effective implementation of pdca cycle increases duration. Learn more about the pdca cycle and how to implement the model at asq.org. Adoption of the pdca cycle in the healthcare industry will have a plethora of benefits. The model is often used at an organisational level, but can also be used at an operational level. Originally developed by american physicist walter a. After evaluation and possible adjustment, the process is restarted. The physicist walter andrew shewhart already had this insight in the 1930s. First, proposed by walter shewhart and later developed by william deming, the pdca cycle became a widespread framework for constant improvements in manufacturing, management, and other areas. Additionally, tqm, the iso standards and the a3 using the pdca cycle encourages the methodical way of problem solving and implementing solutions. Pdca cycle is pdca circle. What is pdca cycle in tqm? More success with the deming cycle.

Any new idea to improve the existing processes goes through the pdca pdca cycle. Since then it has been more often called the deming cycle or deming circle after dr.deming.

Pdca Cycle In Tqm: This is an established tool for achieving continuous improvements to your business.

Fonte: Pdca Cycle In Tqm